Paper Doll Goes on a Field Trip: SMEAD

I was never much for field trips. The Williamsville, NY school district had a penchant for taking us on field trips to farms. I guess they figured that suburban kids had a strong need to see silos and cows. I visited Tifft Farms Nature Preserve so many times in elementary school that I could probably lead a workshop on the proper method of tapping maple syrup in the rain. (As room mother, Paper Mommy came on a lot of these field trips. One senses she, too, was not entirely enamored of the process.)

On Friday, however, I went on a field trip that was a little more in line with Paper Doll sensibilities. I drove down to Atlanta, and then my colleagues, Michelle Grey and Laura Ray, and I carpooled to continue the journey to Locust Grove, GA (population: 5402) to visit Smead.

Our chapter members were made to feel at ease immediately. We were welcomed

THE LESSON PLAN

Customer Sales Coordinator Jenae Brown offered up a PowerPoint presentation on Smead’s history and products. Most of us were already Smead devotees, so we were familiar with a bit of the history. We knew Smead:

- was founded in 1906 when Charles Smead created a “bandless file” for safely filing documents

- has been a woman-owned company for more than 50 years

- began producing all paper products with recycled materials 21 years ago, and has many products made of 100% post-consumer recycled materials

- makes 4999 products for organizing paper and information

We were, however, surprised to learn that Smead had an entire custom-made products division. Not only can Smead design customized printing and/or labeling, unique color options and specialized positioning of fasteners, but these options aren’t limited to big businesses with big budgets and the ability to purchase in big lots. In most cases, the minimum quantity requirement is for only 500 items (per color and/or tab position)! Your small business, non-profit, alumni event committee (or whatever) could create unique, customized folders, portfolios, or binder covers for really reasonable prices.

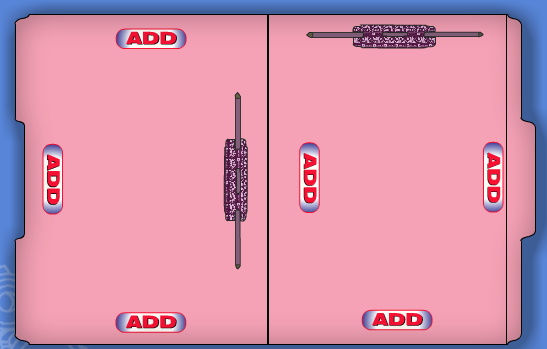

Speaking of customizing, all of our NAPO field trip attendees were intrigued by Smead’s new online Folder Designer. Start by picking the document size (letter or legal) and tab style (top tab — what we think of as a typical file folder — or end tab, like what you’d see in a dentist’s or doctor’s office).

Next, pick your materials. You have a choice of:

- Manila: 11 pt., 14 pt., 18 pt., 100% recycled 11 pt., Antimicrobial Protection 11 pt. or Watershed/Cutless 11 pt. (Because a file folder paper cut REALLY hurts!)

- Kraft: 11 pt. or 17 pt.

- Color: 11 pt., 14 pt., 18 pt. or Watershed/Cutless 11 pt.

- Pressboard: Types 1, 2 or 3

The folder color choices include grey, purple, goldenrod, yellow, blue, orange, green, lavender, white, red and pink (except for the Watershed/Cutless folders, which come in only manila, yellow, green, blue and red).

The pressboard folder color options are more visually subdued but have some intriguing names, like Pacific Blue, Executive Red and a pale hospital green they call “Gopher”.

The next choice regards expansion. You can choose between regular folders with simple scoring on the bottom to expand the folders for larger interior contents or W-fold, enabling a more heavy-duty box-bottom style folder.

Now you get to choose your tabbing! (Can you all imagine Paper Doll rubbing her hands together, Mr. Burns-style, in twitterpated glee over all of these options?)

We tend to think of file folders coming in two styles: 1/3 cut or 1/5 cut (with those tiny tabs requiring tiny labels). Within either of these two styles, you can specify that you only want, for example, left 1/3 cut tabs, or right-of-center 1/5 cut tabs. But there are other tab styles as well, including straight cut (where the tab runs the entire width of the folder), 1/2 cut, and two different styles of 2/5 cut, available at right-of-center or flush right. There are also Alpha Z file folder tabs, which run 8 inches, covering two-thirds of the folder top.

The next step involves selecting whether you want single or two-ply folders, and whether you want a fastener (to allow you to attach papers), in what position,

and of what type, including bonded, embedded, U-style or the Safe-Shield version we’ve reviewed previously.

If this weren’t already a mind-boggling array of customization options worthy of the world’s niftiest ice cream parlor, the Folder Designer also lets one select the number and placement of interior folder dividers and upload any graphics before arranging for a vendor quote for the desired specifications. Whoa!

I’d like to think we pleased Ms. Brown and her colleagues with our enthusiasm, though a discussion of individual products led to a rather rambunctious free-for-all with otherwise calm and staid professional organizers offering up their own suggestions for changes and new product lines. I think we fancied ourselves Smead’s newly appointed adjunct Research & Development team.

THE TOUR

As a paper geek who finds the annual NAPO Conference and Expo to be akin to attending ComicCon, I’d say visiting Smead to see the workings of the factory and warehouse is a bit like going behind the scenes on a Spielberg film set. The only factories I’ve ever visited have been those producing ice cream (Ben & Jerry‘s, Mayfield). Our friends at Smead did not require us to wear hairnets, but as we entered the factory floor, we did have to wear ear plugs. Also, in order to protect Smead’s proprietary methods, we were not allowed to take photographs on the factory floor.

My colleagues and I joked that if one had never visited a factory (or even if one had), the whole experience seemed very much like the opening sequence of Laverne & Shirley, with conveyor belts moving materials from place to place.

The Locust Grove Smead plant employs 178 individuals, the vast majority of whom work on the factory floor. I think we were all surprised to see, even in this age of advanced mechanization, how essential the employees are to the manufacturing process. We learned that Smead follows Lean production practices, an organized (and organizing) philosophy focusing on efficiency, but this efficiency was obviously not at the expense of the dignity or individuality of the employees. In the warehouse, we saw enormous two-story rack systems emblazoned with signs noting that “Row 17 is proudly overseen by…” and various employees’ names.

I think many of us were also surprised to see and learn exactly how the absolutely gigantic rolls of paper (which, when stacked, made us all feel like we were actually behind the scenes at a Land of the Giants remake) became the file folders, hanging folders and other office supplies we use every day.

See those towers behind us? Those are multiple rolls of (wrapped) file folder material.

Our tour guide, Distribution Manager David Wilson (pictured below, with your intrepid blogger),

showed us how just one machine is able to punch out left-, center- and right-tabbed manila and colored folders without being reset, which he explained was a significant change from when he was first on the floor 33 years ago, and the machine had to be reset after each folder style was cut.

We also learned how vast wheels of colored plastic about the width of a grocery store receipt get heated, folded and cut to turn into the hanging file folder tabs we know so well, and got to see first-hand how those fasteners aren’t just glued onto folders, but actually “punched” into and embedded in the folder material.

THE GOODY BAG

All of our chapter’s field trip attendees got a goody bag of Smead products. Our tour liaison, Regional Sales Director David Warwick, engaged us in discussion of the attributes of these items, most of which have been reviewed previously on the Paper Doll blog:

- SuperTab file folders with oversized tabs

- FasTab Hanging Folders with build-in tabs

- Tuff Hanging Folders with Easy Slide Tab

We each also received a sample pink file folder from Smead’s line of File for the Cure in support of breast cancer research, a pressboard classification folder with dividers and SafeShield fasteners

and a spiffy Secure Pocket with Easy Grip  like the one I reviewed last April. (Scroll way down.)

like the one I reviewed last April. (Scroll way down.)

Our goody bags also included some items in Smead’s newest line of attractive and functional presentation products, which will be the subject of an upcoming presentation-themed post.

SAYING GOODBYE

Before we shuffled off to have a delicious lunch at Locust Grove’s famed The French Market Tavern and Grille, we took a moment to get a snapshot of our Smead hosts

(From left: Jenae Brown, David Wilson, NAPO-GA President Sherry Lee Denton, Calvin Ruffin, David Warwick, Donald Plummer, Danny Beheler, Eric Thompson)

No cows. No silos. And no tapping maple syrup in the rain. It was a great field trip!

Now go ahead and sing the Laverne & Shirley theme song…you know you’ve been wanting to do it, and as far as Paper Doll can tell, Smead doesn’t have it’s own theme song yet!

One…two…three…four…shlemiel, shlemazel…Hasenpfeffer Incorporated!

Follow Me