Going Green Around the Earth(Day)–Environmentally-Friendly Paper

This Thursday, April 22, 2010, is the 40th Earth Day. In celebration, Paper Doll has traveled the globe (from the keyboard, maintaining a small carbon footprint) to identify some unusual and environmentally-friendly paper options.

The typical paper used in copiers, faxes and printers used to be “virgin”. Trees got cut down and turned into paper, while society got chain letters and photocopies of people’s tushies, and our forests started looking sparse. Then there was recycled paper, but even it was originally made from trees. Today, we’ve got some international alternatives to paper’s usual provenance, making it a little bit easier, if a little weirder, to be green.

Spinning Straw Into…Copy Paper?

Nature’s Paper reminds me of Rumplestilskin, who exacted a price for helping the imprisoned farmer’s daughter spin straw into gold. Considering that our natural resources are precious, it’s not that surprising to learn that now we can manufacture copy paper from straw.

In Australia alone, tens of millions of trees are cut each year to produce paper for the Down Under populace, but Nature’s Paper has developed a way to turn leftover wheat straw into paper instead.

Normally, when wheat is harvested, grain is used to produce goodies like cereal and flour, but the wheat straw and waste hull are left behind to decompose. Nature’s Paper gathers that wheat straw and converts it into a paper pulp. Then, they power their industrial plant and heat the recycled water they use to clean the paper, all with an organic biofuel made from the the waste hull.

While the typical paper whitening process involves bleach or chlorine, which can only be used twice before disposal (often risking ground water contamination), Nature’s Paper has a chlorine- and bleach-free, sustainable process to safely whiten the pulp to create bright, white copy paper. They even manage to convert their manufacturing waste product into the cardboard boxes to hold the paper!

Reviewers say Nature’s Paper looks and feels just like wood-based copy paper. Check it out yourself — request a sample from its U.S. distributor, Enviro Green.

Can We Still Play Rock, Paper, Scissors If It’s Rock, Rock, Scissors?

If you didn’t have paper, you could get your message across by writing a short note on a rock and throwing it in someone’s direction. A few companies are taking that a step further, bypassing the possibility for concussion, and creating paper out of stone.

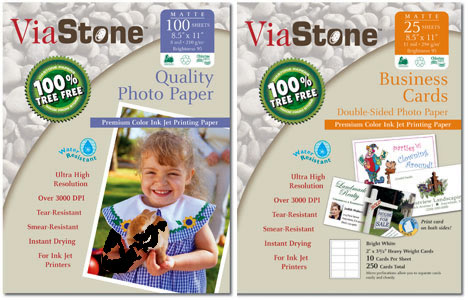

ViaStone’s biodegradable, tree-free paper production requires no toxins, chemicals or even water, and is designed specifically to work with inkjet printers. ViaStone’s process creates paper from a combination of natural stone, mineral powder and some trace non-toxic resins. (California-based Via Stone’s website is still under construction; perhaps it’s hard to build a computer out of stone.)

Obviously, rock paper isn’t quite as sustainable as that made from wheat straw–we can’t grow new rocks. If the extraction of limestone were exponentially increased to make paper from stone available in large quantities, at a level competitive with tree-based paper products, there would be some impact on our balance of resources, but certainly nothing approaching that used to make conventional photo printing or card stock paper from trees.

ViaStone isn’t the only stone cold eco-friendly solution out there.

TerraSkin is made of 75% mineral powder and 25% non-toxic resin, and like other stone paper products, requires no water for production, and therefore creates no water-based pollutants, and inorganic mineral powder residue can either be reused as part of the production process or returned to nature.

Next, TerraSkin’s high proportions of inorganic mineral powder mean that used paper will degrade back into mineral powder when left out in nature within approximately three to nine months–so whether it becomes litter or landfill, it will have minimal environmental impact. Or, one could incinerate TerraSkin paper because the non-toxic resins won’t emit smoke or poisonous gas by-products.

In addition to photo-quality paper, TerraSkin has been used in everything from Burt’s Bees’ soap wrappers to the Metropolitan Museum of Art’s glossy gift bags.

Of course, few people are willing to make a trade-off, compromising on quality in order to be environmentally friendly. (Remember learning cursive writing on that recycled lined paper? I swear, there were small twigs sticking out of that stuff!) TerraSkin is becoming renowned for its unique texture and nifty printing capabilities. Paper made from rock has no fibers, so it doesn’t absorb ink like tree-based paper, and uses about one-third less ink than regular paper. The ink doesn’t bleed, so the paper delivers crisper, cleaner, images. Like other stone-based paper, TerraSkin is also very durable–it’s tear-resistant, water-resistant and strong.

FiberStone is another major player in the rock paper business. It’s composed of about about 80% calcium carbonate, the limestone collected as waste material from quarries used for the construction industry, with about 20% high density polyethylene, a non-toxic resin. The resin acts as a binder for the mineral powder, creating a water- and tear- resistant paper that is nonetheless soft, smooth, and of bright white quality. Also like other stone paper products, production of FiberStone’s Natural Stone Paper requires no water and causes no toxins to enter the air or groundwater. Production is acid-free, bleach-free, chlorine-free…and guilt-free.

FiberStone’s paper takes a little longer to photo/bio-decompose than others — approximately 14-18 months. However, it also seems to have slightly more applications than just copy, photo and premium coated paper for inkjet printers. It’s also suitable for synthetic paper and film products (like Tyvek envelopes and medical packaging), green shipping/packaging supplies and PVC sheeting. It’s even FDA-approved for use in bulk and individual food packaging for shelf-stable and refrigerated or frozen foods. And, because, like all stone paper, it’s water-, grease- and tear-resistant, it’s ideal for field journals or even sob-resistant diaries for prone-to-tears teenagers.

FiberStone paper products are only available through a few affiliate vendors, but you can request a sample of FiberStone’s eco-friendly adhesive labels.

Would Paper By Any Other Name Taste As Sweet?

O’Bon is an environmentally-minded school and office supply company originally known for a line of pencils made from newspaper instead of wood. O’Bon is passionate about running programs to educate children about sustainability and the environment, deforestation and recycling, so it’s no surprise they’d jump at producing paper products made from bagasse, a sugarcane pulp. (Sugarcane is weed-like, requiring little fertilizer or water, making it an excellent sustainable crop.) O’Bon’s line of bagasse-based notebooks are strikingly colorful and vivid, with 100% recycled cardstock covers and sugarcane pulp pages lined with soy-based inks.

Oh, POOP!!!

Mr. Ellie Pooh is a line of paper made from, well, elephant poop. And not just any elephant poop, but Sri Lankan elephant poop…and therein lies a tale.

Approximately one-tenth of the world’s 40,000 Asian elephant population lives in Sri Lanka, in a precarious balance with a populace that finds them an inconvenience. In other parts of the world, elephants are killed for their tusks to supply the ivory trade, or for their meat, but in Sri Lanka, the agricultural community has killed the elephants to prevent them from trampling their crops and destroying their only source of revenue.

Mr. Ellie Pooh is a company that hopes to prove to the Sri Lankans that the elephants can be economically valuable for a new, environmentally sustainable, revenue source. Not to get too scatological, elephants are vegetarians, so their waste is nearly 100% raw cellulose. Mr. Ellie Pooh has developed a manufacturing process that cleans the elephant dung, collected from inhabitants at Sri Lankan elephant orphanages, and combines 75% cleaned dung with 25% post-consumer (recycled) paper to create a hygienic, acid-free (and odor-free), linen-quality, papyrus-like paper with a delicate texture suitable for writing and crafts.

Mr. Ellie Pooh paper production involves no toxic chemicals, and the bonding agents used are all natural, including alum and rosin, with water-soluble salt-based dyes for coloring. The 100% handmade paper products products are bleach-free and acid-free, and the perfect pH for use in photo albums and scrapbooks.

The company has partnered with elephant paper specialists Maximus, on Project Peace Paper, to help reduce the long-standing conflicts between humans and elephants in Sri Lanka’s rural villages. They plan to launch paper re-cycling plants in multiple rural areas and provide training in paper making techniques to the villagers, helping develop a larger sustainable industry.

So, no trees are harmed in the production of this type of paper, and with an average adult elephant producing up to 50 kilograms of dung per day, this paper can be a reliable, renewable source of income for Sri Lankans, thereby improving the plight of the elephants. Mr. Ellie Pooh products can be purchased at scrapbook supply stores, zoos, and various paper vendors throughout North America.

Mr. Ellie Pooh isn’t the first company in the field. In case you’re wondering how someone got the idea to make paper from elephant waste in the first place, that’s the story of a Mr. Wanchai of the bluntly-named Elephant Dung Paper. After visiting a local natural paper production facility and later, the Thai Elephant Conservation Center, he put number two and number two together and paper-making history was made.

Creative Paper Wales, the only craft paper company in all of Wales, was not to be outdone by the pachyderms of Sri Lanka. With their paper mill, located in the adorably-named Snowdonia National Park, Creative Paper Wales produces paper products like holiday and greeting cards, writing paper sets, gift wrap and wedding invitations…

…all from cellulose fiber extracted from Welsh sheep.

Collected sheep waste is completely sterilized by boiling in a special pressure cooker at over 120 degrees centigrade, and then washed repeatedly until it’s been reduced to half its original weight, yielding fibers for the paper process and a by-product of sterile liquid fertilizer that is made available to local farmers.

Cellulose fiber is blended with other recycled pulps, sieved, and then sheets are stacked and layered with felt to keep them from adhering to one another. Immense pressure squeezes out any remaining water, causing the cellulose fibers to tightly bond, making it unexpectedly strong. Finally, the papers are hung to dry in the mill’s roof rafters.

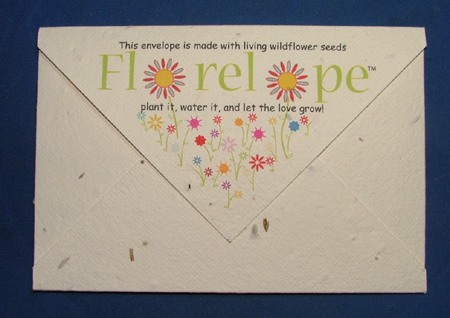

Creative Paper Wales doesn’t just make paper from sheep stuff–they also use waste paper, textile mill cutoffs and rag. Their Florevelopes™ are made with living wildflower seeds, so after you read a letter, you can tear up the envelope, soak it overnight in water and plant it…to grow more wildflowers!

Who would have imagined that straw, stone, sugarcane and…something else, could all be used to create paper that reduces adverse environmental impact? We can only imagine what paper products the future has in store. Happy Earth Day!

Follow Me